Is pottery an art or a craft?

In Japan, there is no clear distinction between the two. In this country, we tend to elevate something called ‘Art’, and in consequence, demote what we call ‘craft’.

The distinction can be clear or muddled.

Imagine two circles which overlap by half their diameter. Call the left circle Art and the right one Craft. An oil painting clearly fits into the left circle of Art. A mug, thrown by hand and almost identical to many others we would agree is a work of craft. Now what about a piece of painted porcelain an original work like no other? It falls around the place where the two concepts overlap. By the same token, a painting which is done many times by somebody trained to paint it, each one only marginally different but essentially similar, might be though I of as craft work, not an art work.

So why worry about these categories? One reason concerns price. Craft, having a lower status commands a lower price than art. By charging a high price, people can shift the perceived status of an object from craft to art. A banana, by being taped to a wall in an art gallery and sold for an exotic sum, can metamorphise from fruit to artwork.

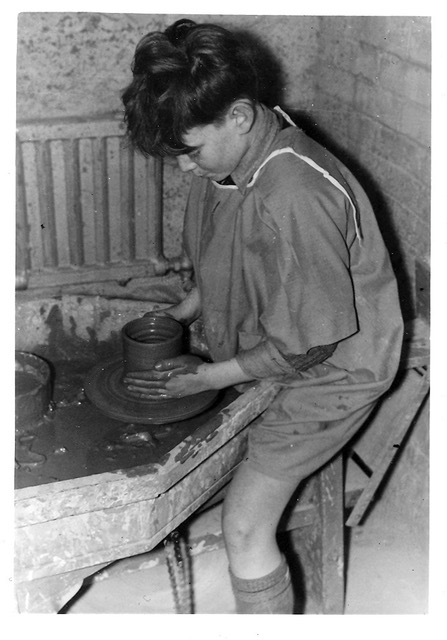

Does craftwork always have a use? Traditionally yes, since everything was made by hand, useful things were naturally made that way. Waggons and wheelbarrows, pots and pans- all were the product by skilled artisans or craftsmen. In today’s world where everything we need is made in vast quantities and costs little, craftsmen and women have turned more and more to making objects which have no use. Because they are unusual, or even unique, they share to that extent the quality of art. They may or may not be beautiful, but they gain credibility by being different.

To return to the opening question- it depends upon the intention of the maker.

In our case, we are grounded in the teaching of Bernard Leach, so most of our work is made to be used. However in making reduction fired lustreware, we are leaning towards the art side of that diagram. We make bowls which have little use, but people buy then because they are beautiful. Lamp bases and vases can be useful and beautiful. Large lustre plates can be to hung on the wall- this also signifies an art object.